Restore the Power.

Recapture the Value.

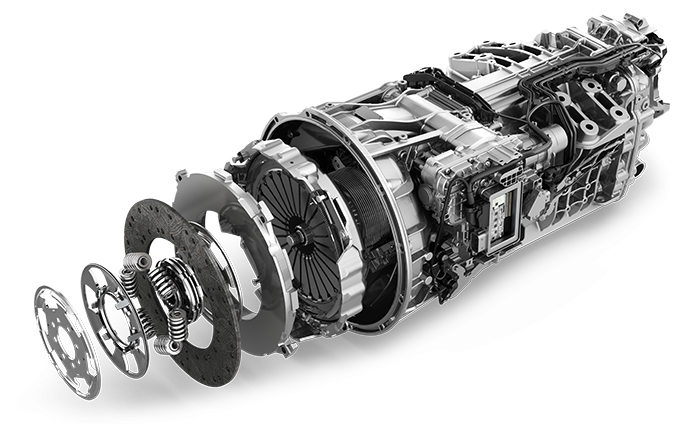

Understanding the Remanufacturing Process.

1/4

Discover the Value of Remanufacturing.

Some things you have to see to believe. At Detroit Reman, we want our customers to understand the passion behind what we do. We believe that the best way to do that is by visiting one of our facilities and experiencing our process first-hand.

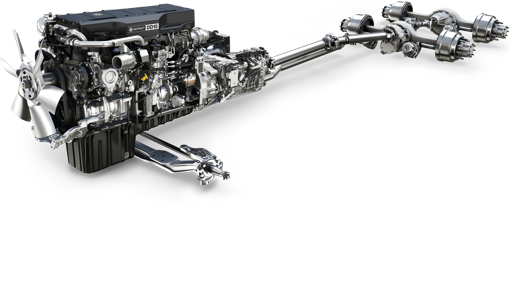

The Detroit Reman Product Portfolio

The Benefits of Remanufacturing.

Detroit Reman's experience and expertise in the remanufacturing technology and process provide key benefits for OEM's including:

-

Off-shelf components increase productivity and decrease down time

-

Process includes latest technology and engineering standards

-

Operational testing back to manufacturers specs

-

100% Disassembly and inspection of every remanufactured part

-

Billing and core credits are handled promptly through the Detroit Reman System