Advanced Technology

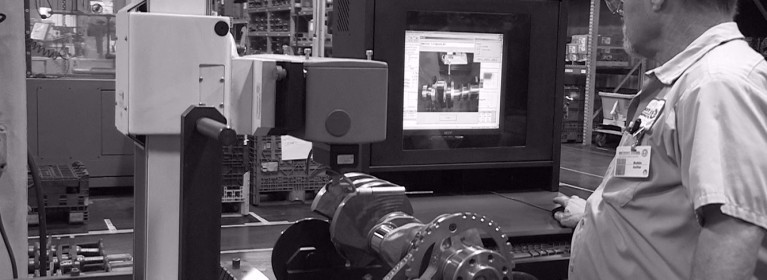

High Tech Capabilities.

Detroit Reman's advanced capabilities include restoration of the materials of worn surfaces. Processes such as cold spray and thermal spray welding allow us to return a product to its original specifications eliminating the need for oversized components.

Twin Wire Arc Process

The twin wire arc welding uses two wires as the base coating material and is most commonly sprayed on a flat or sealing surfaces. The wires are atomized using an electrical charge and a pressurized inert gas is used to apply it onto the surface. The mechanical properties of the coating can be customized to improve wear characteristics.

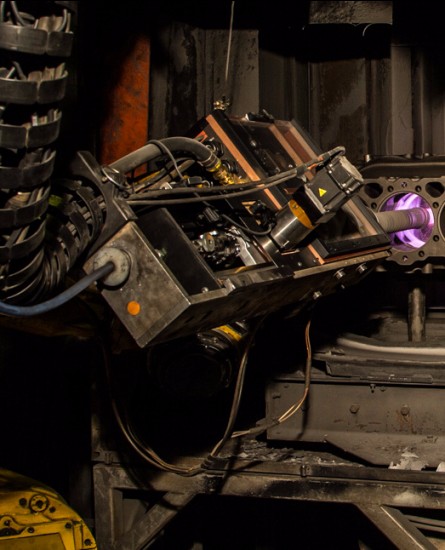

Plasma Transferred Wire Arc

This process uses a single welding wire and plasma gas with a small application head to coat hard to reach areas such as inner diameter surfaces. The surface can then be machined or even honed to the original specification.

Supersonic Spray

This process allows the recovery of a wide variety of components made of aluminum or cast iron that have cosmetic or sealing surface damage. The process applies metal at a high velocity and introduces very little heat into the base component, eliminating the possibility of distortion. This process can minimize cost by eliminating the need to discard a component for an insignificant blemish or flaw.

Submerged Arc Welding

Submerged arc welding is an automated welding process utilized to rebuild metal in thicker quantities. This process is useful in recovering areas that have incurred damage or wear on a surface.